You can share

- Share to Facebook

- Share to Google+

- Subscribe to our

- Share to Linkedin

- Share to Twitter

DBV have professional research and QC team, having international advanced management and technology with endless innovation. We have developed more than 6000 types of valves. And our core technology is the metal to metal seat for butterfly valves and ball valves.

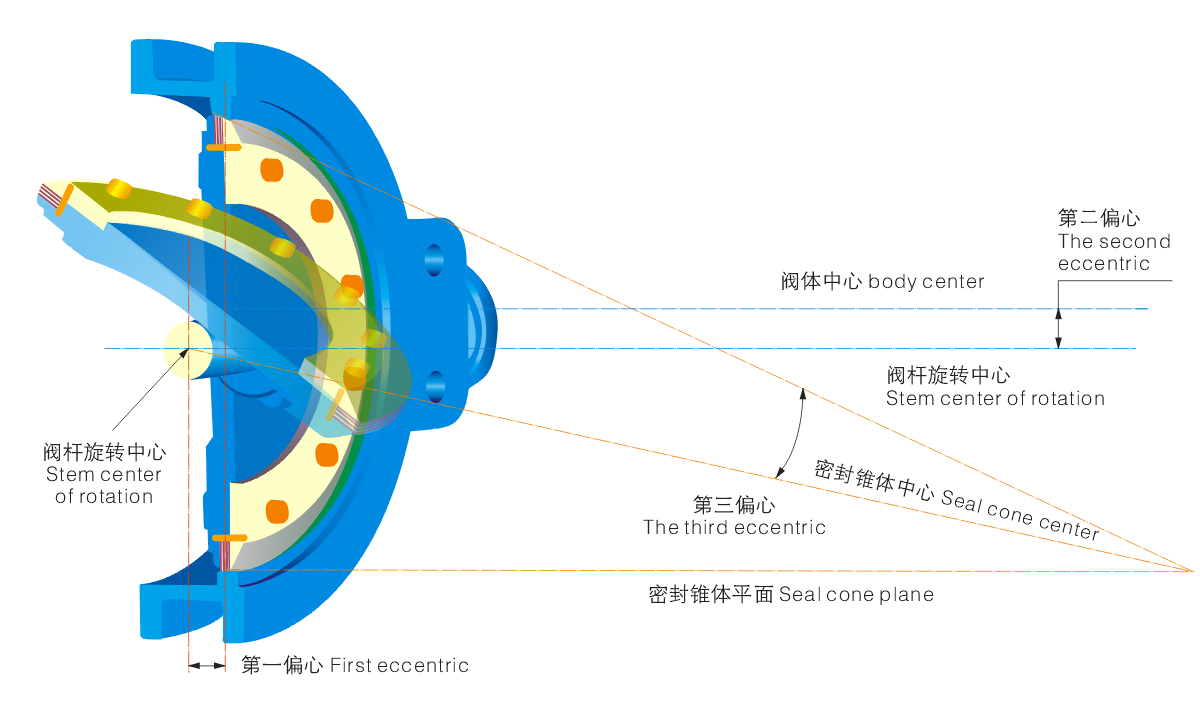

The design features of DBV triple eccentric butterfly valves:

The first eccentricity: the deviation between stem rotation center and the seat centerline ensures a tight seal between the seat and disc.

The second eccentricity: the deviation between stem rotation center and the seat centerline, when the valve opens, can make the butterfly plate leave sealing surface quickly.

The third eccentricity: the deviation between the center of the seal ring’s vertebral body and the seat centerline completely eliminates the friction between disc and seat.

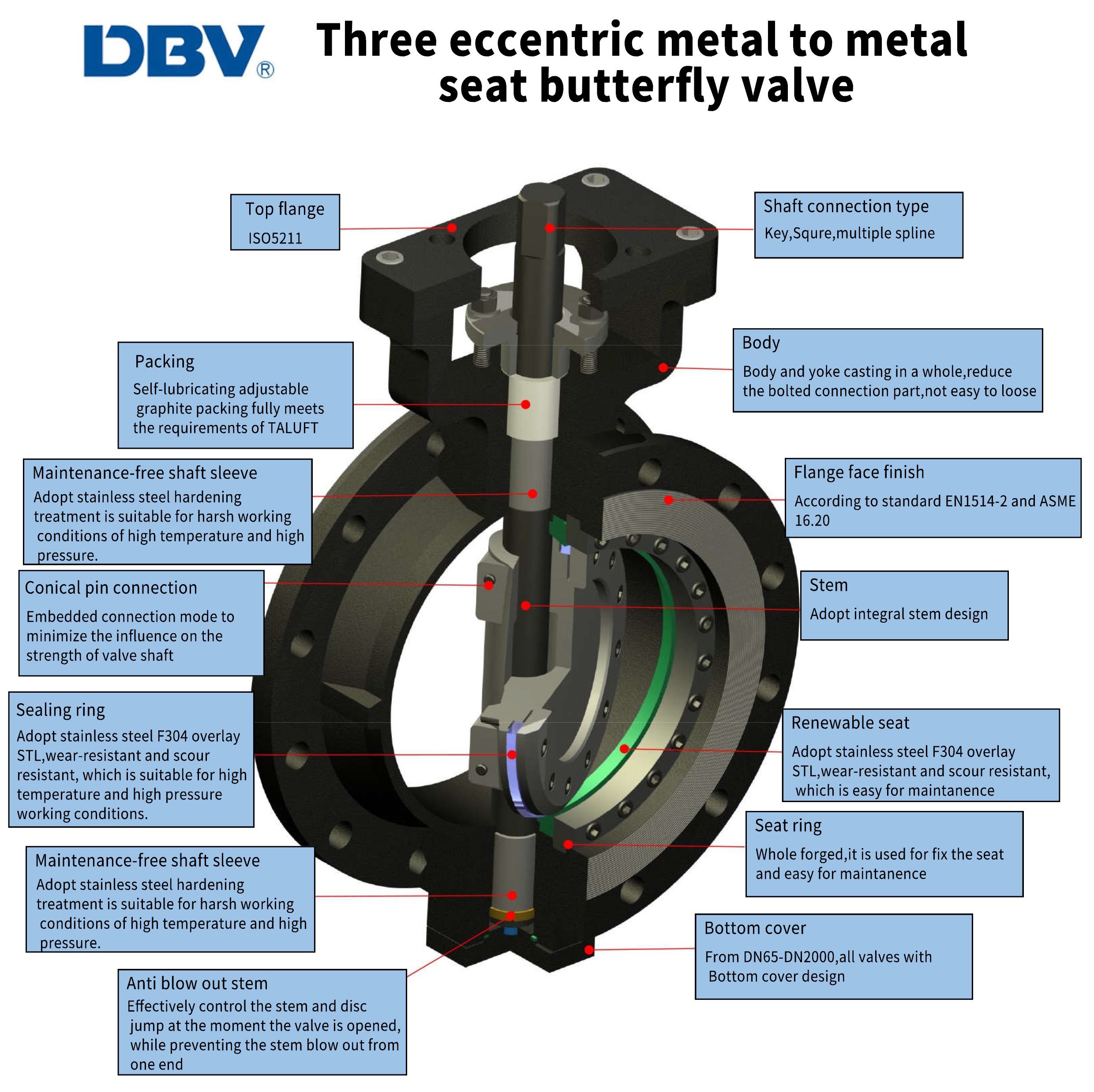

Product Characteristics of DBV metal seat triple eccentric butterfly valves:

1. Elastic property of composite metal sealing ring performs zero leakage.

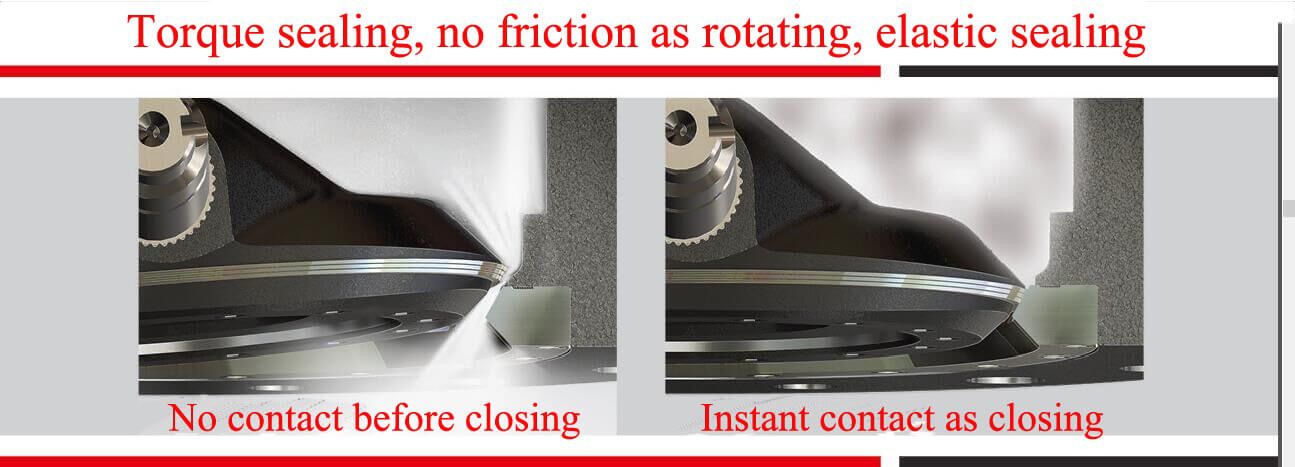

2. Torque seal ensures persistent two-way zero leakage.

3. The design of right-angled rotation with zero friction is implemented by the distinctive triple eccentric principle. It eliminates the friction between the seat and sealing ring in 90degree rotation.

4. STL one-piece hard-surface seat may adapt to many working conditions, which is featured by long service life and easy maintenance.

5. One-piece cast(sheet welded) body, face to face dimensions conforming to ISO5752, ASME B16.1, and API609, can be replacement to high performance butterfly valves and other types of valves, with easy and flexible installation.

6. All metal structure and zero leakage performance make the valve have the property of nature fireproof safety.

7. Anti-blowout stem for high dependability completely conforms to API609.

8. The valve position indictor on the stem and the flange mounted at the top are in favor of the indication of disc position.

9. The stem of triple eccentric butterfly valve is a shaft structure, stem and disc and connected by pin-key combination.

DBV VALVES MERITS:

Low Switching Torque:

DBV butterfly valve series adopt the sealing design of triple eccentric, flexible multi-layer metal and graphite superimposed to ensure good sealing performance and reduce operating torque.

Zero Leakage:

Multi-layer seal self-positioning design, satisfies the demands of API598 zero leakage.

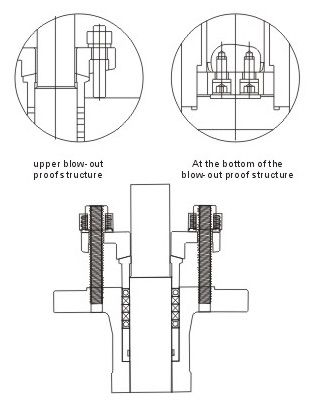

Blow Out Proof Stem:

DBV butterfly valve adopts double blow out proof stem design, according with the requirement of API609 and ANSI B31.1.

Upper: stem bottom slot, embedded split ring, preventing stem blow out.

Bottom: The stem is designed with a step shaft which is matched with the bushing to prevent the valve stem blowing out.

Fire Safe Design:

Metal and piled up multilayer graphite seal design, the inherent fire prevention function, satisfying API607 fire prevention requirements.

Low leakage Stem Seal:

1. Stem is guided and positioned by the stem bearing during the whole course to avoide the case that the stem offset, caused by lateral pressure shock, resulted in the leakage of stem packing.

2. Packing adopts the processing method of pre-compression, of which upper and lower ends use braided graphite rope and the middle uses forming graphite ring, to enhance the anti-leakage performance,

3. The roughness control of stem and packing surface: Stem:Ra0.4~Ra0.8, Packing: Ra1.6.

4. The choice of dynamic load gland flange keeps packing compressed constantly and continuously to reduce the leakage of stem packing seal,

5. According to users’ requirements, the valve stem seal can be designed in accordance with Shell MESC77/312 and TA Luft20PPM is in accordance with the nitrogen suction method.

DBV Owns many patents of all kinds of valves, like patents of ball valves, butterfly valves, gate valves, globe valves, check valves, etc.