You can share

- Share to Facebook

- Share to Google+

- Subscribe to our

- Share to Linkedin

- Share to Twitter

You can share

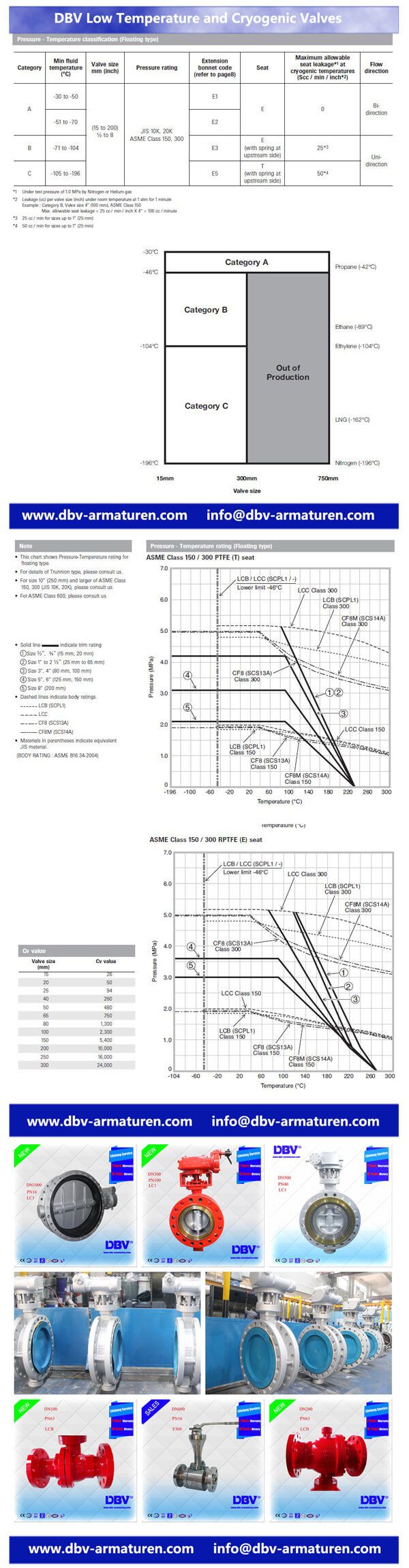

DBV Butterfly Valves& Ball Valves have been widely applied in cryogenic service, including Liquid Nitrogen, which is becoming the best unchangeable supplier.

Features

1. Sub-zero treatment as special -196℃treatment.

2. Permanent non-deformation as rigid body construction

3. Zero leakage sealing as excellent seat and seal design

4. No freeze-damage as long neck designed

5. Firm treated stem as Chrome plating or nitriding.

6. Self-pressure relief struction

7. Fugitive emissions control for flammable application.

8. Second sealing as grease.

International Designed:

Cryogenic Flange/Wafer Metal Seat Butterfly Valves( Wholly metal seat, Metal to Metal, Metal laminated with Graphite Seat,Mutilayer Seat) :

|

Design Standard |

GB |

BS EN |

API |

|

Technical requirements of Cryogenic Butterfly Valves for low temperature situation |

GB/T24925 |

BS6364 |

MSS SP-134 |

|

Design Standard |

GB/T12238 |

BS EN593 |

API609 |

|

Face-to-Face |

GB/T12221 |

BS EN558 |

API609 |

|

Connection End/Flanged |

GB/T9113 |

BS EN 1092-1 |

ASME B16.5 |

|

Test and Inspection |

GB/T13927 |

BS EN12266 |

API598 |

|

The end type and dimensions can be desinged and manufactured according to the buyers' requirements. |

|||

|

Main Parts and Materials: |

|

|

Part Name |

low Temp.Steel/Stainless Steel Material |

|

Body |

A352-LCB, A352-LCC, A350-LF2, A351-CF8, A351-CF8M, A182-F304,A182-F316 |

|

Disc |

A350-LF2+ENP, A182-F304,A182-F316 |

|

Stem |

A350-LF2,A276-304,A276-316 |

|

Seal ring/Seat |

PEEK,NYLON,DEVLON,PTFE,PCTFE |

|

Packing |

PFTE, Lw emission combined packing,Graphite |

|

Bolt/Nut |

A320-L7, A194-4/ A193-B8,A194-8 |