You can share

- Share to Facebook

- Share to Google+

- Subscribe to our

- Share to Linkedin

- Share to Twitter

DBV can make a large range of ‘chrome-moly valves. Our valves are manufactured from low alloy steel +chromium and molybdenum so to be suitable for higher temperature service especially for higher pressure and temperature combinations. In addition, these valves have the added advantage of anti-corrosive properties. Our valve material have forged ASTMA182 F5, F5a, F9, F11 and F22, and their casting equivalent to ASTM A217 C5, C12, WC5, WC6 and WC9., and more ASTM A217 Grade C12A Cast Cr-Mo-V Steel is available.

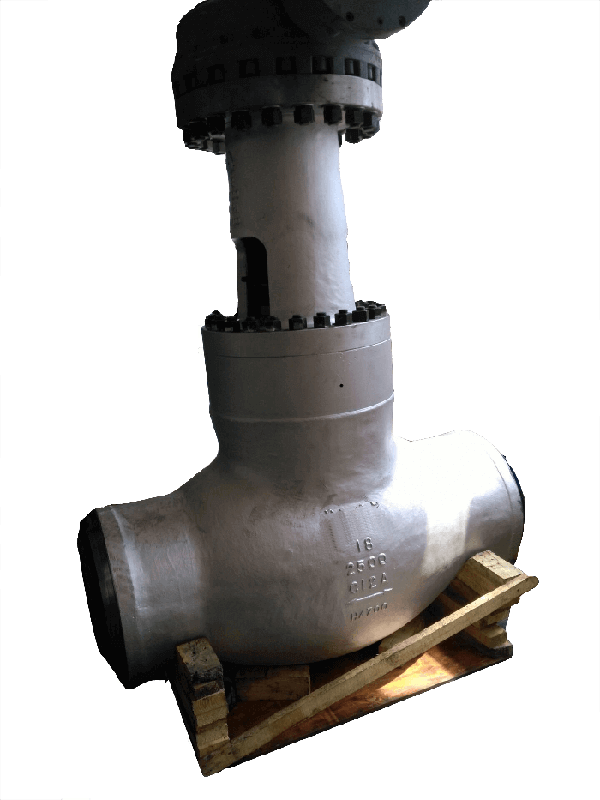

See our latest C12A valves as bellow:

ASTM A217 Grade C12-A is a very special casting steel material for supercritical power station valves. Seldom factories in china can successfully make it as it is difficult to casting and welding because lack of Nitrogen, easy oxidation of niobium and vanadium element.

1. DBV has serious control of the chemical composition of C12A.

Here is the chemical composition table of the C12A as bellow:

|

C |

Si |

Mn |

P |

S |

Cr |

|

0.08 ~0.12 |

0.20~0.50 |

0.30 ~0. 60 |

≤0.020 |

≤0.010 |

8.0~9.5 |

|

Mo |

Nb |

V |

N |

Ni |

Al |

|

0.85 ~1.05 |

0.06~0.10 |

0.18 ~0.25 |

0.03 ~0.07 |

≤0. 4 |

≤0.04 |

The elements Cr, Mn, Mo, Nb, V will low the activity of the Ni elements in the steel, improve the Ni dissolving ability in the steel. So when casting C12A, we shall seriously control the inside composition as following: the harmful elements will be controlled as Wp< 0. 010% Ws <0. 005%; Cr as the max limit; Wal=0. 01% ~ 0. 03%.

The company controlling chemical composition is as bellow:

|

C |

Si |

Mn |

P |

S |

Cr |

|

0.08 ~0.10 |

0.20~0.40 |

0.40 ~0. 60 |

≤0.010 |

≤0.005 |

8.5~9.5 |

|

Mo |

Nb |

V |

N |

Ni |

Al |

|

0.9 ~1.0 |

0.06~0.08 |

0.18 ~0.25 |

0.03 ~0.045 |

≤0. 4 |

0.01~0.03 |

And table of mechanical characteristics for C12A:

|

No. |

σb /MPa |

σs / MPa |

δ ( % ) |

ψ ( %) |

|

Standard |

585 ~ 760 |

≥415 |

≥20 |

≥45 |

The related important conditions as bellow:

|

Forging code |

Composition |

Material code |

Service application |

Trim 150#-600# |

Trim 900#-2500# |

|

A182 F91 |

9% Chrome; 1% Moly; V-N, Medium Alloy Steel |

ASTM A217 Grade C12-A |

Mild corrosive or erosive applications as well as non-corrosive applications at temperatures between -30ºC (-20ºF) and +650ºC (+1200ºF). |

8 8A 12/12A |

5/5A |

DBV valve group is one of the few manufacturers in developing the C12A super alloy steel material for valves. We warmly welcome all customers and technician from the world to improve the valve technology together for the better future of world.