You can share

- Share to Facebook

- Share to Google+

- Subscribe to our

- Share to Linkedin

- Share to Twitter

You can share

In

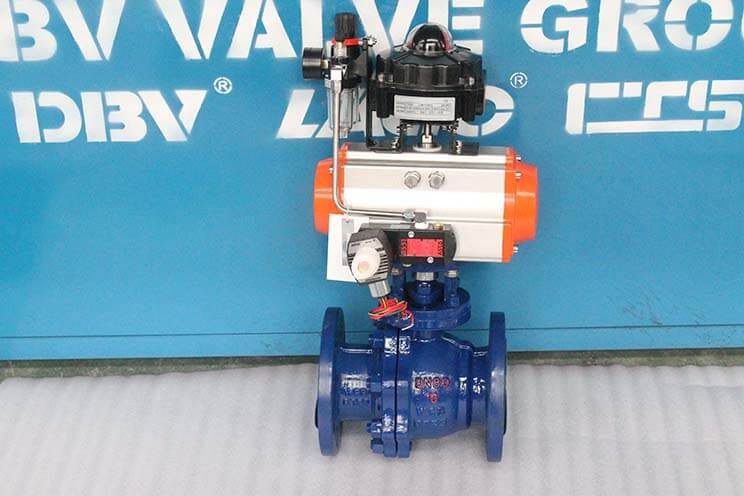

the pipeline, pneumatic ball valve is mainly used to quickly shut off flow ,

which also distribute and change the flow direction of the medium. It is convenient

to be maintained because its structure is simple. And in general the sealing

ring is movable, so it is easy to be disassembled and replaced.

With the continuous evolution of the valve production process, different types of pneumatic ball valve have emerged and sealing type and material requirements are not the same. To use it can reduce the product types of production line, which is suitable for piping system of light structure, low pressure(small differential pressure) and corrosive medium. Therefore, it is important to pay attention to the operation and ensure the operation of pneumatic ball valve is safe so that person is safe.

Before

operation, check whether there is any heavy abrasion on seal ring or not, if so, it is

necessary to be maintained. People should safely deal with the frequent wear of

metal and ensure the normal production of enterprise equipment. Although the

pneumatic ball valve is easy to be managed, it can't be taken lightly. And it should

be operated by professional operators to reduce accidents.