You can share

- Share to Facebook

- Share to Google+

- Subscribe to our

- Share to Linkedin

- Share to Twitter

You can share

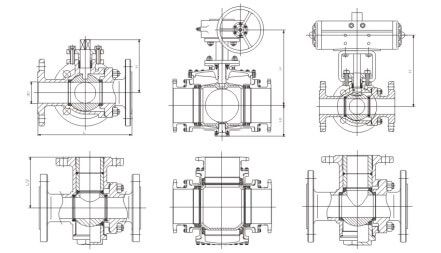

1.The valve seat can be designed as four sides of floating ball or trunnion mounted ball, with smooth fluid state and reliable sealing.

2.The structure can be designed as installed by side or at the top and no mixed flowing when changing the flow direction.

3.The stem is designed as blow-out proof.

4. Anti-static design.

5. Two position(on and off) lockup design.

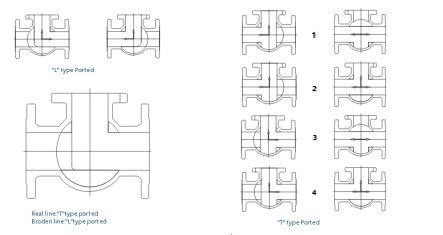

Three way ball valves are used for switching, mixing and separating the flow of corrosive or non corrosive liquid, gas or power mediums -46℃-+200℃. Upon opening and closing, the smooth flow channel reduces pressure loss, making operation quite labor-saving and maintenance fairly easy. The five types of flow direction ( L type and T type ) meet different technological requirements. It can be manually, pneumatically and electrically operated.