You can share

- Share to Facebook

- Share to Google+

- Subscribe to our

- Share to Linkedin

- Share to Twitter

You can share

| Product Description |

|---|

|

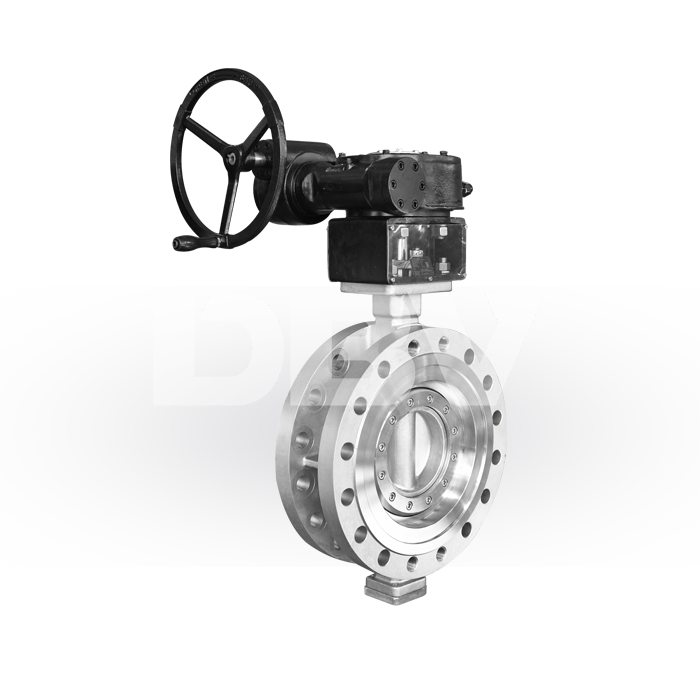

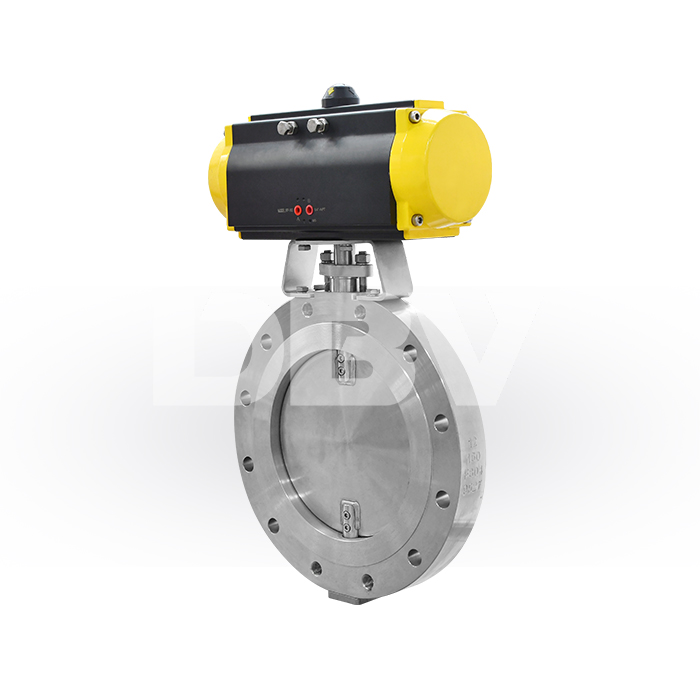

The DN300 High-Performance Metal Seated Butterfly Valve is engineered for demanding industrial applications, offering exceptional durability and reliability. Its metal-seated design ensures long-lasting performance, even in harsh environments with high temperatures, abrasive media, or corrosive conditions. This valve is ideal for industries such as power generation, oil & gas, and chemical processing. With a robust construction and precision sealing, it guarantees minimal leakage and optimal flow control under high-pressure conditions. |

| Product Features |

|---|

|

Metal Seated Design: High-Performance Sealing: Large Bore (DN300): Robust Construction: Easy Maintenance: |

| Materials |

|---|

|

Body: Disc: Seat: Stem: |

| Size and Dimensions |

|---|

|

Nominal Diameter (DN): Pressure Rating: End Connections: Face-to-Face Dimensions: |

| Standards |

|---|

|

Design and Manufacturing: Pressure Testing: Flange Standards: Material Standards: |

| Applications |

|---|

|

Power Generation: Oil & Gas: Chemical Processing: Mining & Metal Industries: |

|

Optimize your industrial processes with our DN300 High-Performance Metal Seated Butterfly Valve, engineered for demanding applications. This valve is designed with a durable metal seat, providing exceptional resistance to wear, heat, and pressure, making it ideal for industries such as oil and gas, chemical processing, and power generation. The high-performance design ensures a tight, reliable seal, even in extreme conditions, while offering precise flow control. Built for longevity and efficiency, the DN300 butterfly valve guarantees minimal maintenance and reliable operation, making it a cost-effective solution for high-demand systems. Choose our DN300 metal seated butterfly valve for unmatched durability and performance in your industrial applications. |

| Production R&D & Own Factory |

|---|

|

| Contact us /Email |

| info@dbv-armaturen.com |

| factory Address |

| No.96 Fanhua East Road,OuBei,WenZhou,Zhejiang,China,325102 |

| Social Media |

|